After gaining some experience launching a few High Altitude Balloons (HABs): http://wiki.032.la/habex2 , http://wiki.032.la/habexpico1

I found myself designing smaller and smaller HABs and after the radio cutout on HABEXpico1 (suspected to be due to cold temperatures) I decided it would be a good idea to create an environmental chamber that would replicate the conditions of nearspace.

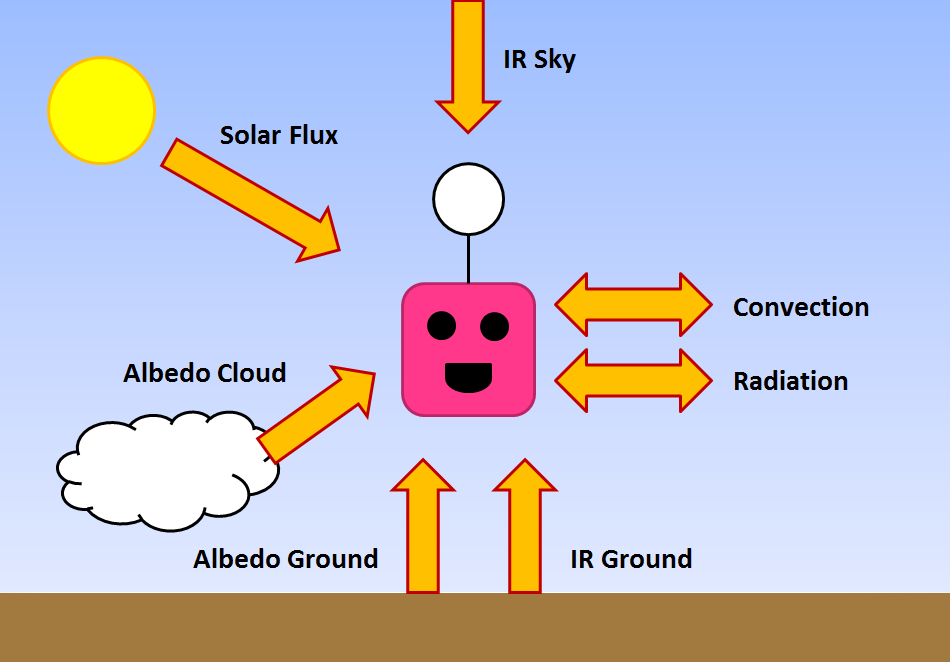

The conditions of nearspace aren’t too kind to electronics. Air temperature can be anywhere from -60C to +40C, the air pressure at the average burst altitude of 30,000m (100,000ft) is 1% of the pressure on the ground. Electronics dependent on convection for cooling can easily overheat, and the cold temperatures can shut down electronics if they are not rated for those conditions and if the insulation isn’t sufficient.

Expected environmental conditions:

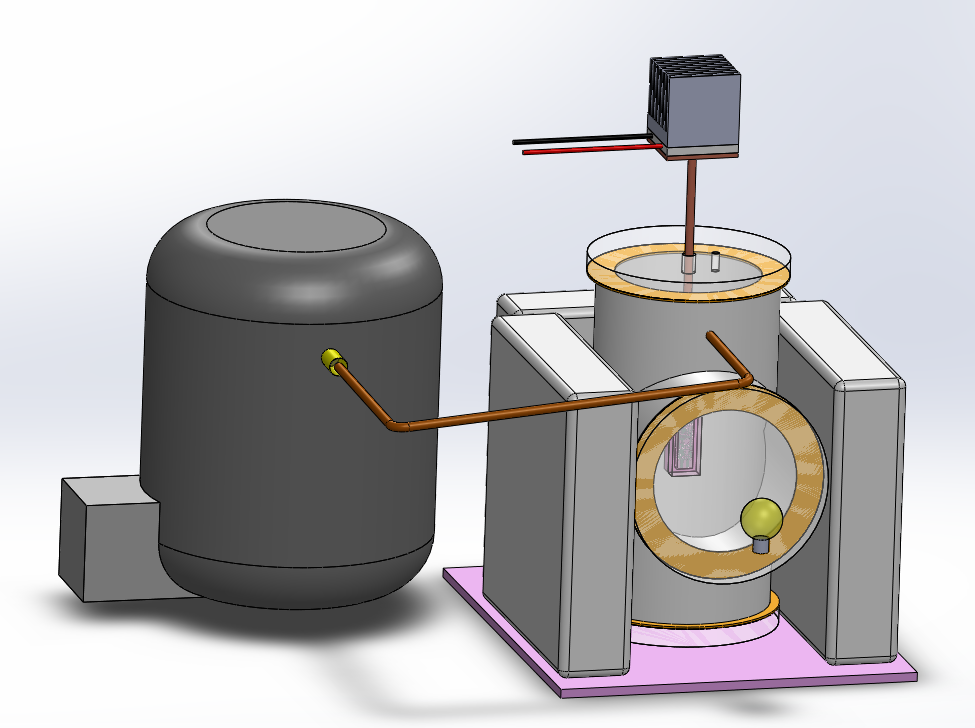

The goal was to build a thermal/vacuum chamber for $100-200 capable of testing and answering the 3 following questions:

1) Can your HAB survive the expected temperatures?

2) How well does your insulation work?

3) Does your HAB overheat? (Do your parts need cooling?)

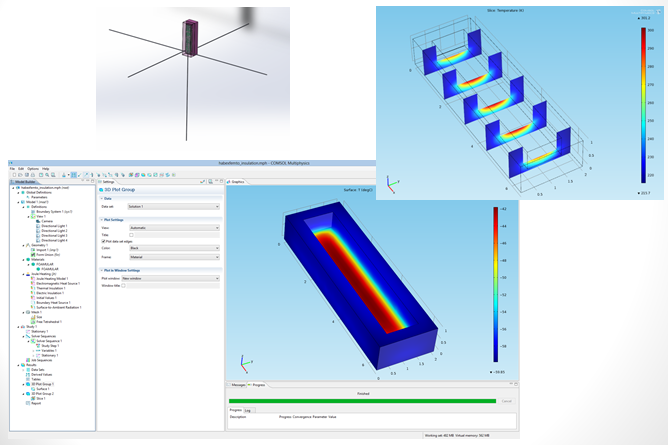

Now you can attempt to do thermal modeling… but that gets tricky. You can save time and get good results by just testing it.

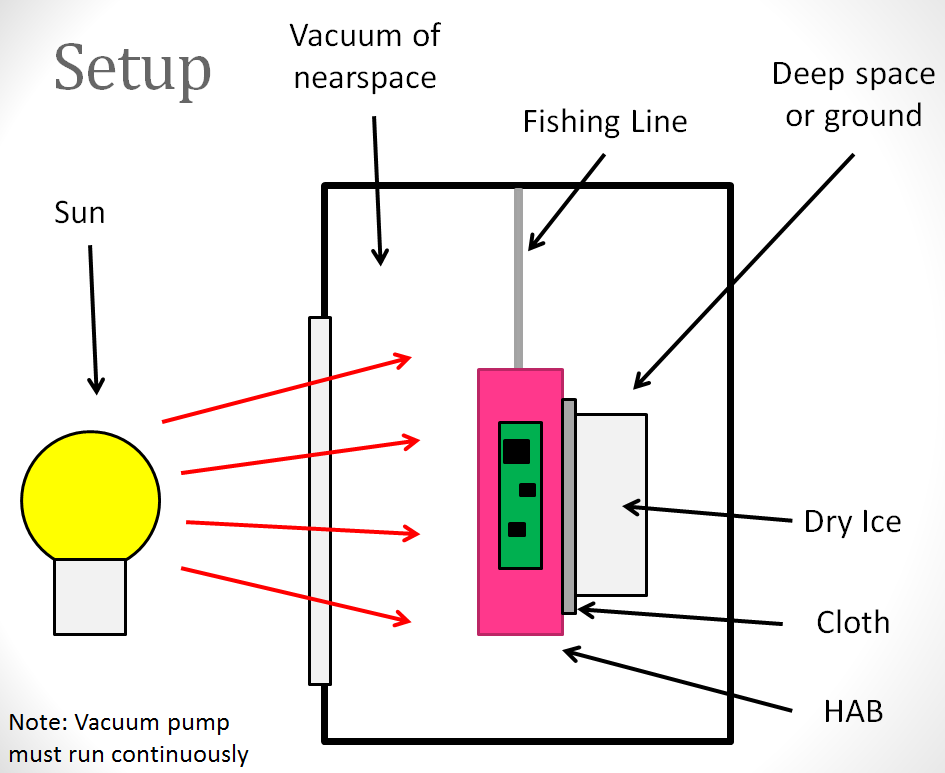

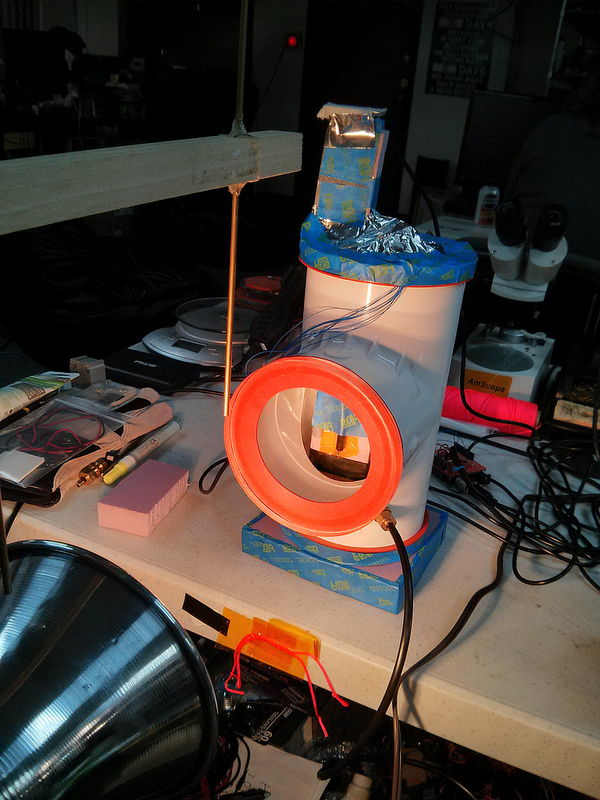

For each environmental condition you can replicate the follow conditions using the following:

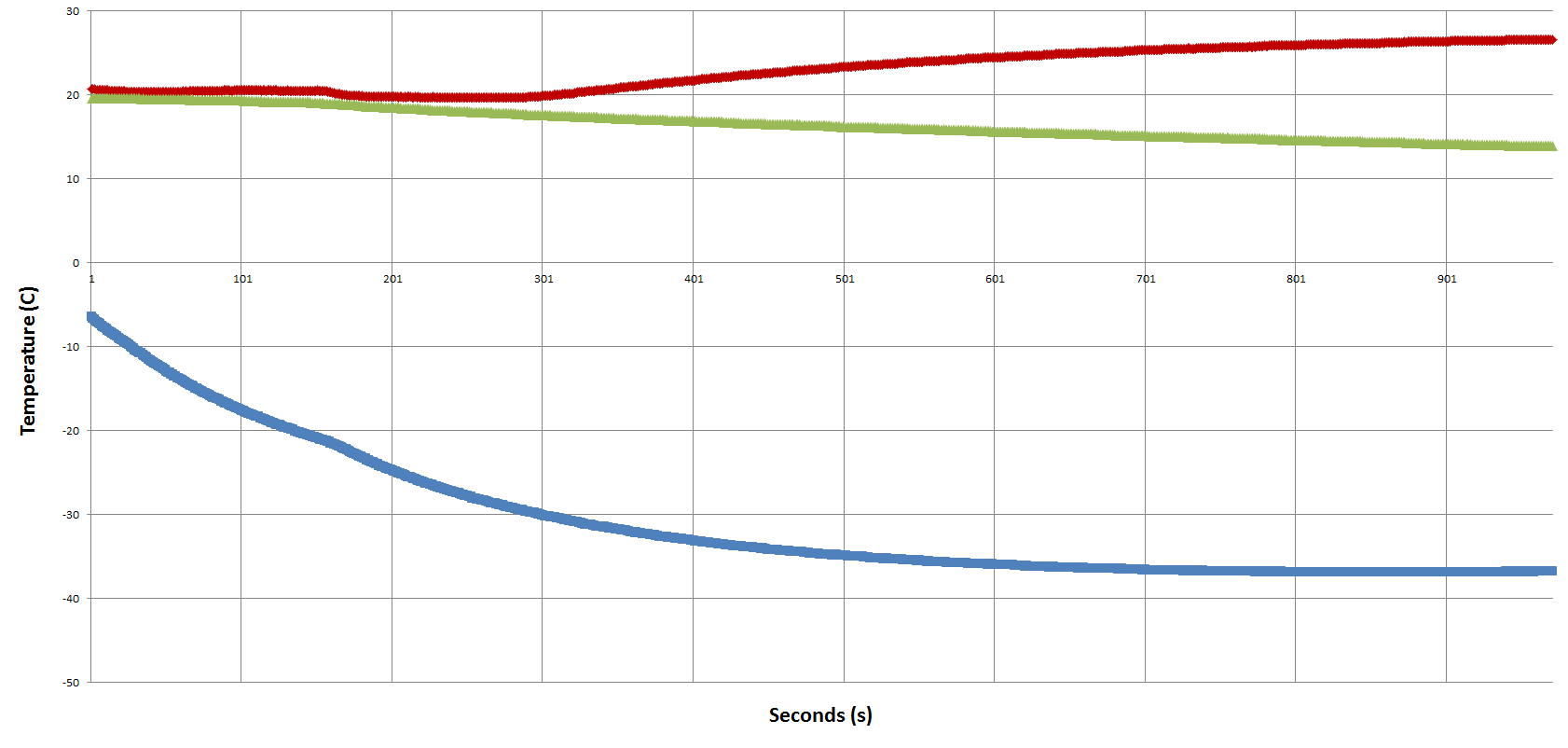

These were the results. The one side facing the “sun” got to about 28C (RED), while the cold side facing “deep space” aka dry ice got the outside of the insulation to about -40C (BLUE), and the inside of the HAB slowly moved down to about 10C (GREEN). Not bad, but not great. The problem with this setup is the fact that the dry ice is thermal interfaced with by conduction, rather than radiation. In a proper thermal vacuum chamber a shroud with liquid nitrogen tubes is run through the walls to produce cold walls. The walls are coated with a material such as black paint (high absorptivity), this forms good radiative thermal coupling. One could improve the design by having this and even placing it on a lazy susan to allow the hab to rotate and spin while the sunlight is applied. However, the setup would cost more than the original budget of “under $200”. Please note that this a “build at your own risk” project. I’m not responsible if your chamber implodes or hurts anyone. Also, do not cool down the PVC itself, that could make it very fragile.

Here’s the cost breakdown:

In my talk I discuss the solutions to solving a hot or cold hab: http://arkorobotics.com/data/UKHAS_2013_arko.pptx

In my extended talk I also discuss solving software, radio/hardware configuration, and EMC (electromagnetic compatibility): http://arkorobotics.com/data/UKHAS_2013_EXTENDED_arko.pptx